Chapter 10 Type 2 & 3 Gauge r&R Study

10.1 Type 2 Gauge r&R Study

The example data are taken from Houf & Berman (1988) and concern the thermal impedance of \(10\) different power modules (in \(^\circ\)C per \(\text{Watt} \times 100\)) as measured by \(3\) different operators. Each operator measured each part \(3\) times:

| Part | Operator | Measurement |

|---|---|---|

| 1 | A | 37 |

| 1 | A | 38 |

| 1 | A | 37 |

| 1 | B | 41 |

| 1 | B | 41 |

| 1 | B | 40 |

| 1 | C | 41 |

| 1 | C | 42 |

| 1 | C | 41 |

| 2 | A | 42 |

| 2 | A | 41 |

| 2 | A | 43 |

| 2 | B | 42 |

| 2 | B | 42 |

| 2 | B | 42 |

| 2 | C | 43 |

| 2 | C | 42 |

| 2 | C | 43 |

| 3 | A | 30 |

| 3 | A | 31 |

| 3 | A | 31 |

| 3 | B | 31 |

| 3 | B | 31 |

| 3 | B | 31 |

| 3 | C | 29 |

| 3 | C | 30 |

| 3 | C | 28 |

| 4 | A | 42 |

| 4 | A | 43 |

| 4 | A | 42 |

| 4 | B | 43 |

| 4 | B | 43 |

| 4 | B | 43 |

| 4 | C | 42 |

| 4 | C | 42 |

| 4 | C | 42 |

| 5 | A | 28 |

| 5 | A | 30 |

| 5 | A | 29 |

| 5 | B | 29 |

| 5 | B | 30 |

| 5 | B | 29 |

| 5 | C | 31 |

| 5 | C | 29 |

| 5 | C | 29 |

| 6 | A | 42 |

| 6 | A | 42 |

| 6 | A | 43 |

| 6 | B | 45 |

| 6 | B | 45 |

| 6 | B | 45 |

| 6 | C | 44 |

| 6 | C | 46 |

| 6 | C | 45 |

| 7 | A | 25 |

| 7 | A | 26 |

| 7 | A | 27 |

| 7 | B | 28 |

| 7 | B | 28 |

| 7 | B | 30 |

| 7 | C | 29 |

| 7 | C | 27 |

| 7 | C | 27 |

| 8 | A | 40 |

| 8 | A | 40 |

| 8 | A | 40 |

| 8 | B | 43 |

| 8 | B | 42 |

| 8 | B | 42 |

| 8 | C | 43 |

| 8 | C | 43 |

| 8 | C | 41 |

| 9 | A | 25 |

| 9 | A | 25 |

| 9 | A | 25 |

| 9 | B | 27 |

| 9 | B | 29 |

| 9 | B | 28 |

| 9 | C | 26 |

| 9 | C | 26 |

| 9 | C | 26 |

| 10 | A | 35 |

| 10 | A | 34 |

| 10 | A | 34 |

| 10 | B | 35 |

| 10 | B | 35 |

| 10 | B | 34 |

| 10 | C | 35 |

| 10 | C | 34 |

| 10 | C | 35 |

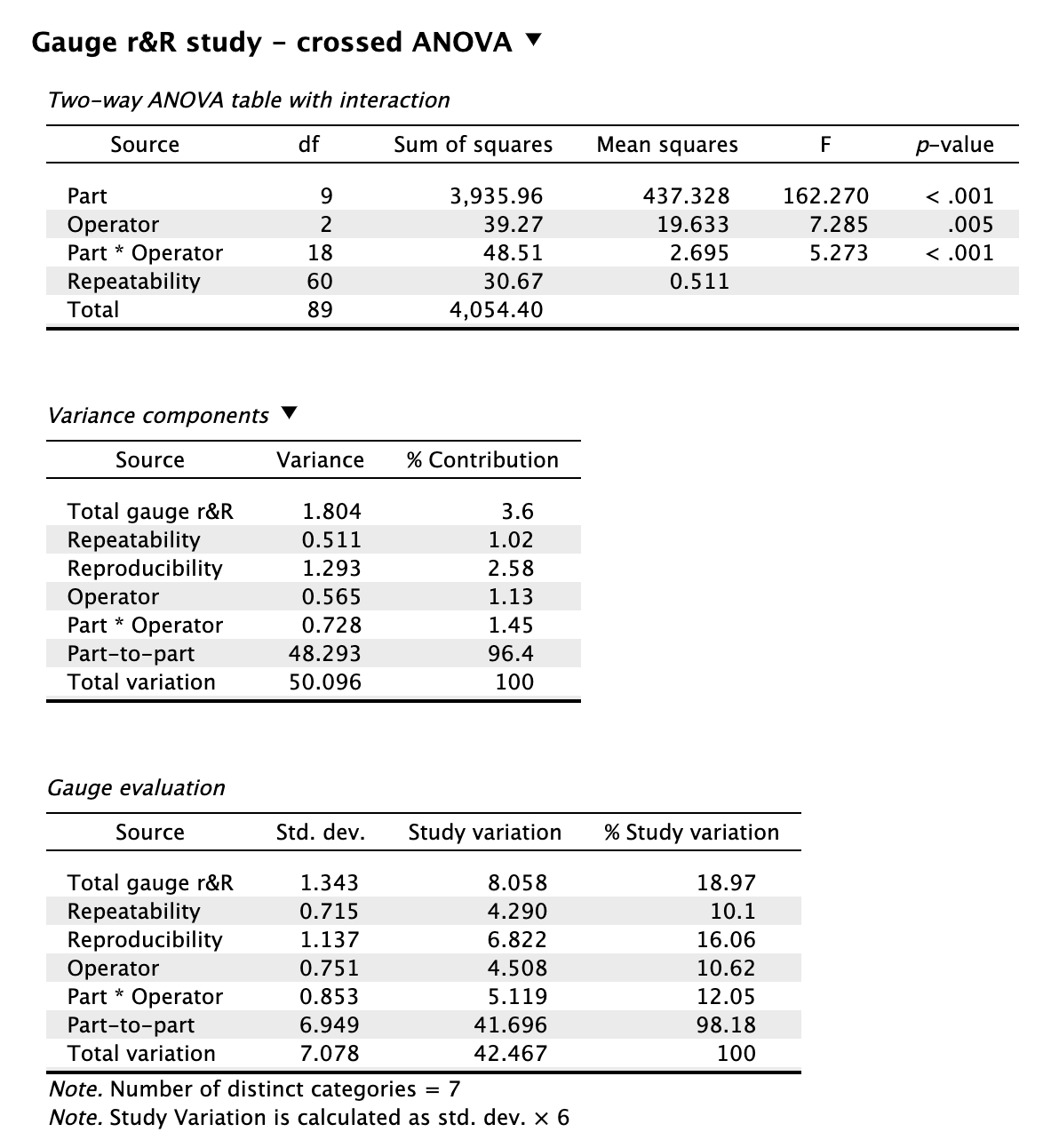

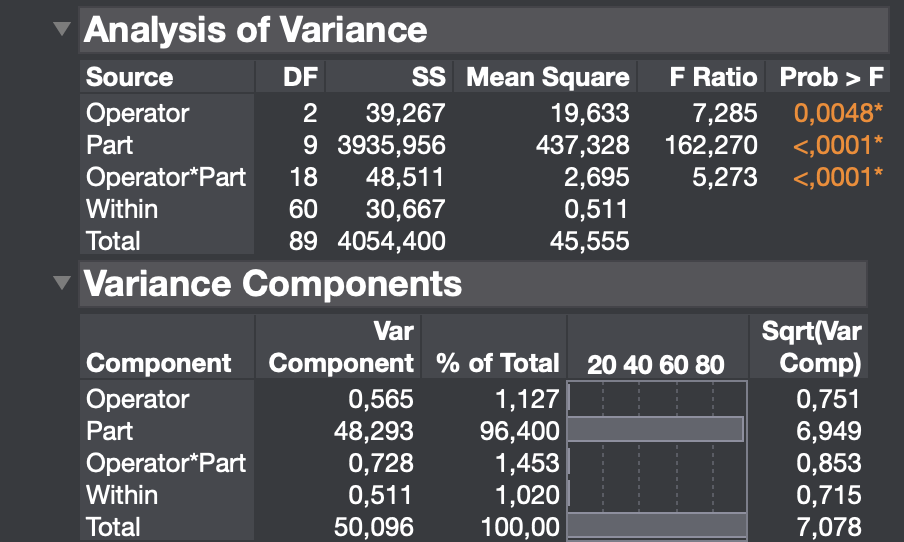

10.1.1 Results Overview

10.1.1.1 Variance Components

| JASP | By Hand | JMP | Minitab | R | |

|---|---|---|---|---|---|

| Total Gage R&R | 1.804 | 1.804 | 1.804 | 1.804 | 1.804 |

| Repeatability | 0.511 | 0.511 | 0.511 | 0.511 | 0.511 |

| Reproducibility | 1.293 | 1.293 | 1.293 | 1.293 | 1.293 |

| Operator | 0.565 | 0.565 | 0.565 | 0.565 | 0.565 |

| Part:Operator | 0.728 | 0.728 | 0.728 | 0.728 | 0.728 |

| Part-To-Part | 48.293 | 48.293 | 48.293 | 48.293 | 48.293 |

| Total Variation | 50.096 | 50.096 | 50.096 | 50.096 | 50.096 |

10.1.1.2 % Contribution

| JASP | By Hand | JMP | Minitab | R | |

|---|---|---|---|---|---|

| Total Gage R&R | 3.60 | 3.60 | 3.60 | 3.60 | 3.60 |

| Repeatability | 1.02 | 1.02 | 1.02 | 1.02 | 1.02 |

| Reproducibility | 2.58 | 2.58 | 2.58 | 2.58 | 2.58 |

| Operator | 1.13 | 1.13 | 1.13 | 1.13 | 1.13 |

| Part:Operator | 1.45 | 1.45 | 1.45 | 1.45 | 1.45 |

| Part-To-Part | 96.40 | 96.40 | 96.40 | 96.40 | 96.40 |

| Total Variation | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

10.1.3 By Hand

# number of levels

o <- nlevels(dat$Operator)

p <- nlevels(dat$Part)

n <- length(dat$Measurement) / (o * p)

# totals

grand_total <- sum(dat$Measurement)

C <- grand_total^2 / (o * p * n)

cell_totals <- with(dat, tapply(Measurement, list(Operator, Part), sum))

row_totals <- rowSums(cell_totals)

col_totals <- colSums(cell_totals)

# SS total

SS_total <- sum(dat$Measurement^2) - C

# SS O (Operator)

SS_O <- sum(row_totals^2) / (p * n) - C

# SS P (Part)

SS_P <- sum(col_totals^2) / (o * n) - C

# SS O×P

SS_OP <- sum(cell_totals^2) / n - SS_O - SS_P - C

# SS error

cell_sumsq <- with(dat, tapply(Measurement, list(Operator, Part), function(x) sum(x^2)))

SS_E <- sum(cell_sumsq - (cell_totals^2)/n)

# degrees of freedom

df_O <- o - 1

df_P <- p - 1

df_OP <- (o - 1) * (p - 1)

df_E <- o * p * (n - 1)

# mean squares

MS_O <- SS_O / df_O

MS_P <- SS_P / df_P

MS_OP <- SS_OP / df_OP

MS_E <- SS_E / df_E

# Variance component estimates assuming that both Operators and Parts are random effects

sigma2_E <- MS_E

sigma2_OP <- (MS_OP - MS_E) / n

sigma2_O <- (MS_O - MS_OP) / (n * p)

sigma2_P <- (MS_P - MS_OP) / (n * o)

reprod <- sigma2_O + sigma2_OP

repeatab <- sigma2_E

gauge <- reprod + repeatab

total <- gauge + sigma2_P

varComp <- c(gauge, repeatab, reprod, sigma2_O, sigma2_OP, sigma2_P, total)

# %Contribution

percContrib <- varComp / total * 100

res <- matrix(c(varComp, percContrib),

nrow = 7, ncol = 2, byrow = FALSE)

colnames(res) <- c("Variance Components", "% Contribution")

rownames(res) <- c("Total Gage R&R", "Repeatability", "Reproducibility", "Operator",

"Part:Operator", "Part-To-Part", "Total Variation")

res## Variance Components % Contribution

## Total Gage R&R 1.8037037 3.600473

## Repeatability 0.5111111 1.020257

## Reproducibility 1.2925926 2.580216

## Operator 0.5646091 1.127047

## Part:Operator 0.7279835 1.453168

## Part-To-Part 48.2925926 96.399527

## Total Variation 50.0962963 100.00000010.1.5 Minitab

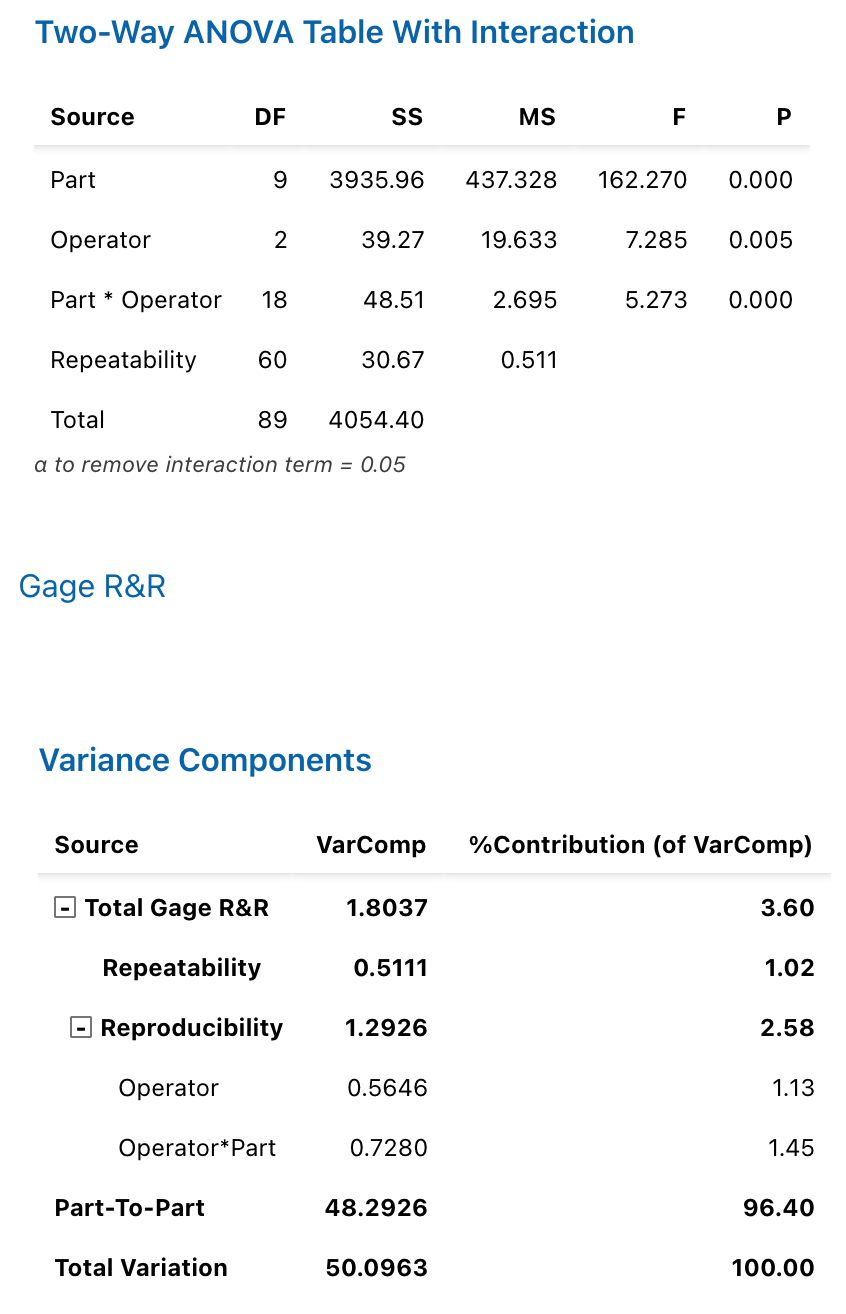

Figure 10.3: Minitab Output for Type 2 Gauge r&R Analysis (Part 1)

Figure 10.4: Minitab Output for Type 2 Gauge r&R Analysis (Part 2)

10.1.6 R

## Complete model (with interaction):

##

## Df Sum Sq Mean Sq F value Pr(>F)

## Part 9 3936 437.3 162.270 2.29e-15

## Operator 2 39 19.6 7.285 0.00481

## Part:Operator 18 49 2.7 5.273 5.06e-07

## Repeatability 60 31 0.5

## Total 89 4054

##

## alpha for removing interaction: 0.05

##

## Gage R&R

##

## VarComp %Contrib

## Total Gage R&R 1.8037037 3.60

## Repeatability 0.5111111 1.02

## Reproducibility 1.2925926 2.58

## Operator 0.5646091 1.13

## Part:Operator 0.7279835 1.45

## Part-To-Part 48.2925926 96.40

## Total Variation 50.0962963 100.00

##

## StdDev StudyVar %StudyVar

## Total Gage R&R 1.3430204 8.058122 18.97

## Repeatability 0.7149204 4.289522 10.10

## Reproducibility 1.1369224 6.821535 16.06

## Operator 0.7514047 4.508428 10.62

## Part:Operator 0.8532195 5.119317 12.05

## Part-To-Part 6.9492872 41.695723 98.18

## Total Variation 7.0778737 42.467242 100.00

##

## Number of Distinct Categories = 710.2 Type 3 Gauge r&R Study

Consider an example from Gadim & Doniavi (2018). The data concern the tensile strength of polymer yarns. Each of the \(30\) yarns was measured \(3\) times:

| Part | Measurement |

|---|---|

| 1 | 1.6245 |

| 1 | 1.6225 |

| 1 | 1.6278 |

| 2 | 1.7277 |

| 2 | 1.7254 |

| 2 | 1.7307 |

| 3 | 1.6847 |

| 3 | 1.6828 |

| 3 | 1.6874 |

| 4 | 1.8249 |

| 4 | 1.8226 |

| 4 | 1.8273 |

| 5 | 1.7114 |

| 5 | 1.7054 |

| 5 | 1.7160 |

| 6 | 1.8072 |

| 6 | 1.8006 |

| 6 | 1.8160 |

| 7 | 1.7681 |

| 7 | 1.7590 |

| 7 | 1.7677 |

| 8 | 1.8650 |

| 8 | 1.8561 |

| 8 | 1.8737 |

| 9 | 1.6670 |

| 9 | 1.6579 |

| 9 | 1.6700 |

| 10 | 1.8546 |

| 10 | 1.8520 |

| 10 | 1.8583 |

| 11 | 1.7948 |

| 11 | 1.7925 |

| 11 | 1.7976 |

| 12 | 1.9814 |

| 12 | 1.9799 |

| 12 | 1.9846 |

| 13 | 1.9046 |

| 13 | 1.9022 |

| 13 | 1.9081 |

| 14 | 2.0546 |

| 14 | 2.0520 |

| 14 | 2.0583 |

| 15 | 1.9654 |

| 15 | 1.9594 |

| 15 | 1.9700 |

| 16 | 2.1570 |

| 16 | 2.1479 |

| 16 | 2.1600 |

| 17 | 1.8684 |

| 17 | 1.8624 |

| 17 | 1.8730 |

| 18 | 2.0548 |

| 18 | 2.0526 |

| 18 | 2.0575 |

| 19 | 1.8109 |

| 19 | 1.8084 |

| 19 | 1.8135 |

| 20 | 1.8896 |

| 20 | 1.8812 |

| 20 | 1.8901 |

| 21 | 1.8840 |

| 21 | 1.8749 |

| 21 | 1.8870 |

| 22 | 1.9694 |

| 22 | 1.9634 |

| 22 | 1.9740 |

| 23 | 1.7645 |

| 23 | 1.7629 |

| 23 | 1.7675 |

| 24 | 1.9130 |

| 24 | 1.9039 |

| 24 | 1.9159 |

| 25 | 1.9415 |

| 25 | 1.9434 |

| 25 | 1.9500 |

| 26 | 1.8774 |

| 26 | 1.8714 |

| 26 | 1.8820 |

| 27 | 1.8737 |

| 27 | 1.8713 |

| 27 | 1.8769 |

| 28 | 1.9076 |

| 28 | 1.8992 |

| 28 | 1.9081 |

| 29 | 1.9550 |

| 29 | 1.9461 |

| 29 | 1.9637 |

| 30 | 1.9046 |

| 30 | 1.9022 |

| 30 | 1.9081 |

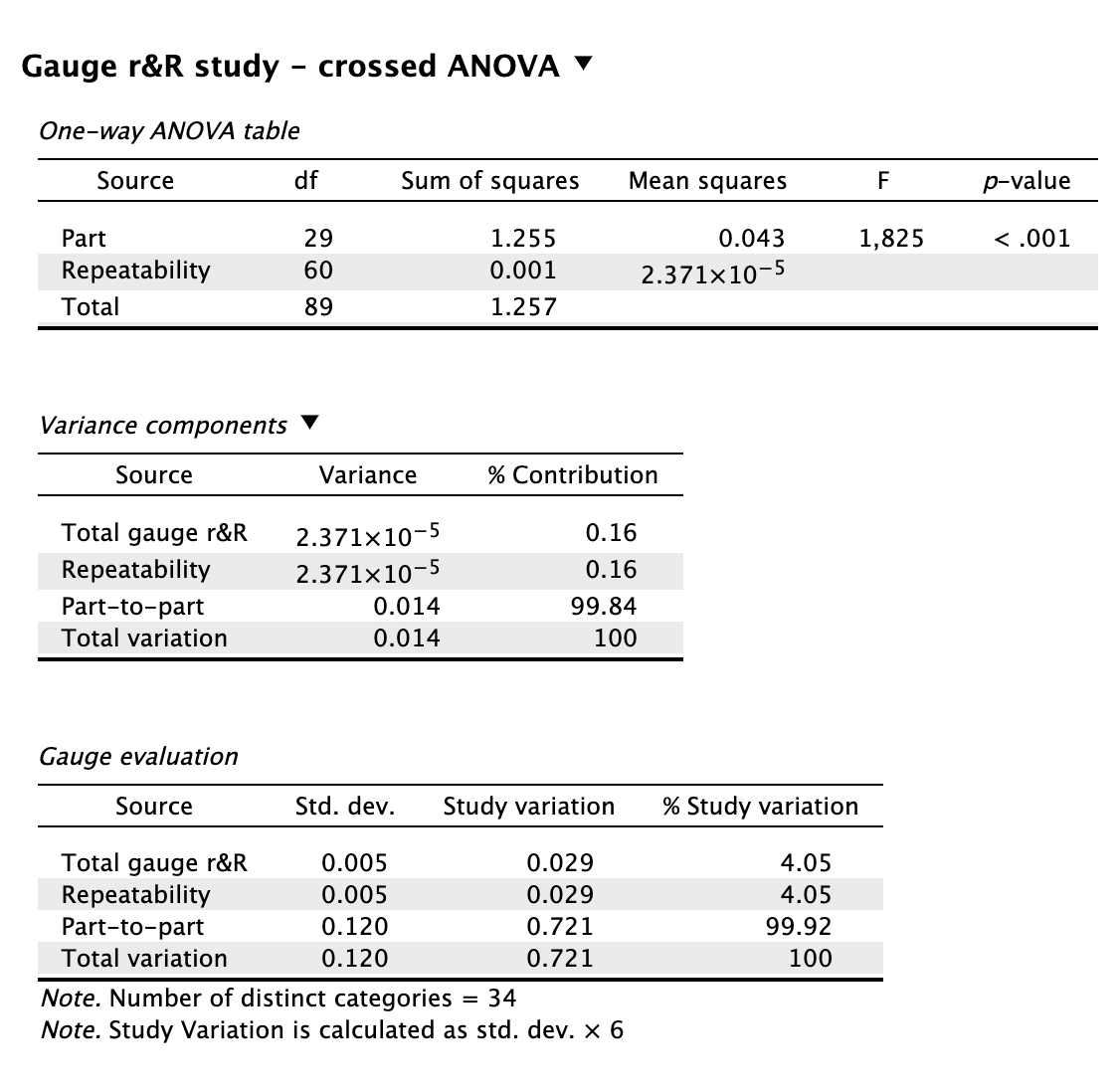

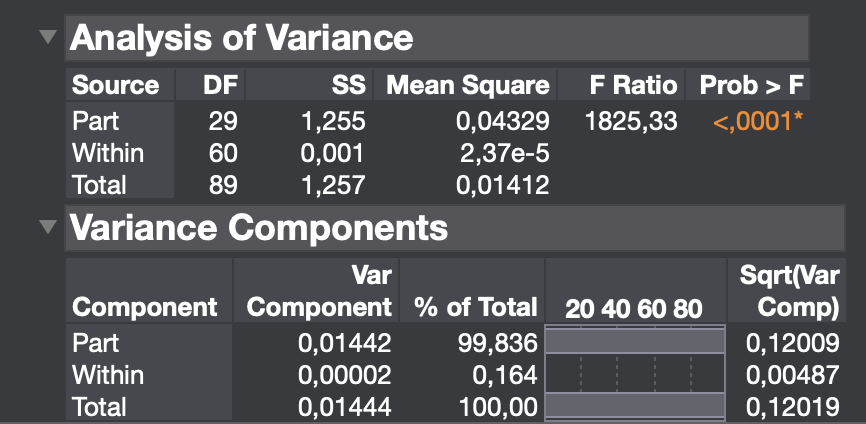

10.2.1 Results Overview

10.2.1.1 Variance Components

| JASP | By Hand | JMP | Minitab | R | |

|---|---|---|---|---|---|

| Total Gage R&R | 2.37e-05 | 2.37e-05 | 0.00002 | 2.37e-05 | 2.37e-05 |

| Repeatability | 2.37e-05 | 2.37e-05 | 0.00002 | 2.37e-05 | 2.37e-05 |

| Part-To-Part | 1.40e-02 | 1.40e-02 | 0.01400 | 1.40e-02 | 1.40e-02 |

| Total Variation | 1.40e-02 | 1.40e-02 | 0.01400 | 1.40e-02 | 1.40e-02 |

10.2.3 By Hand

# number of levels

p <- nlevels(datType3$Part)

n <- length(datType3$Measurement)

r <- n / p

# totals

grand_total <- sum(datType3$Measurement)

# SS total

SS_total <- sum((datType3$Measurement - mean(datType3$Measurement))^2)

# SS part

partMeans <- tapply(datType3$Measurement, datType3$Part, mean)

SS_P <- sum((partMeans - mean(datType3$Measurement))^2) * r

# SS error

deviations <- datType3$Measurement - rep(partMeans, each = r)

SS_E <- sum(deviations^2)

# degrees of freedom

df_P <- p - 1

df_E <- n - p

# mean squares

MS_P <- SS_P / df_P

MS_E <- SS_E / df_E

# Variance components

sigma2_E <- MS_E

sigma2_P <- (MS_P - MS_E) / r

repeatab <- sigma2_E

gauge <- repeatab

total <- gauge + sigma2_P

varComp <- c(gauge, repeatab, sigma2_P, total)

# %Contribution

percContrib <- varComp / total * 100

res <- matrix(c(varComp, percContrib),

nrow = 4, ncol = 2, byrow = FALSE)

colnames(res) <- c("Variance Components", "% Contribution")

rownames(res) <- c("Total Gage R&R", "Repeatability", "Part-To-Part", "Total Variation")

res## Variance Components % Contribution

## Total Gage R&R 0.000023714 0.1641736

## Repeatability 0.000023714 0.1641736

## Part-To-Part 0.014420756 99.8358264

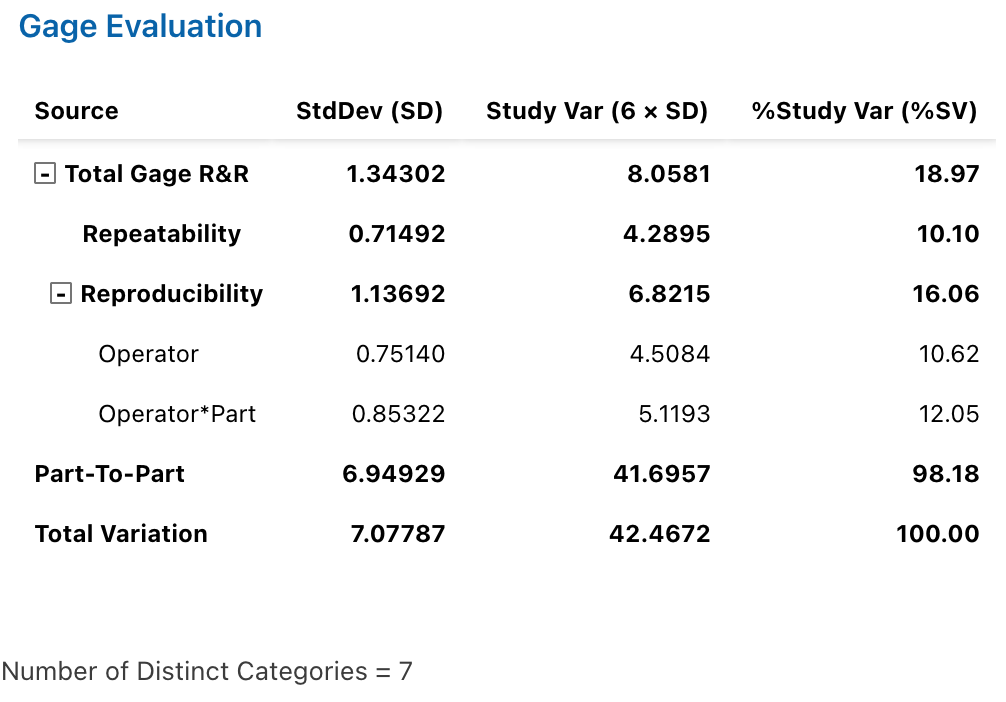

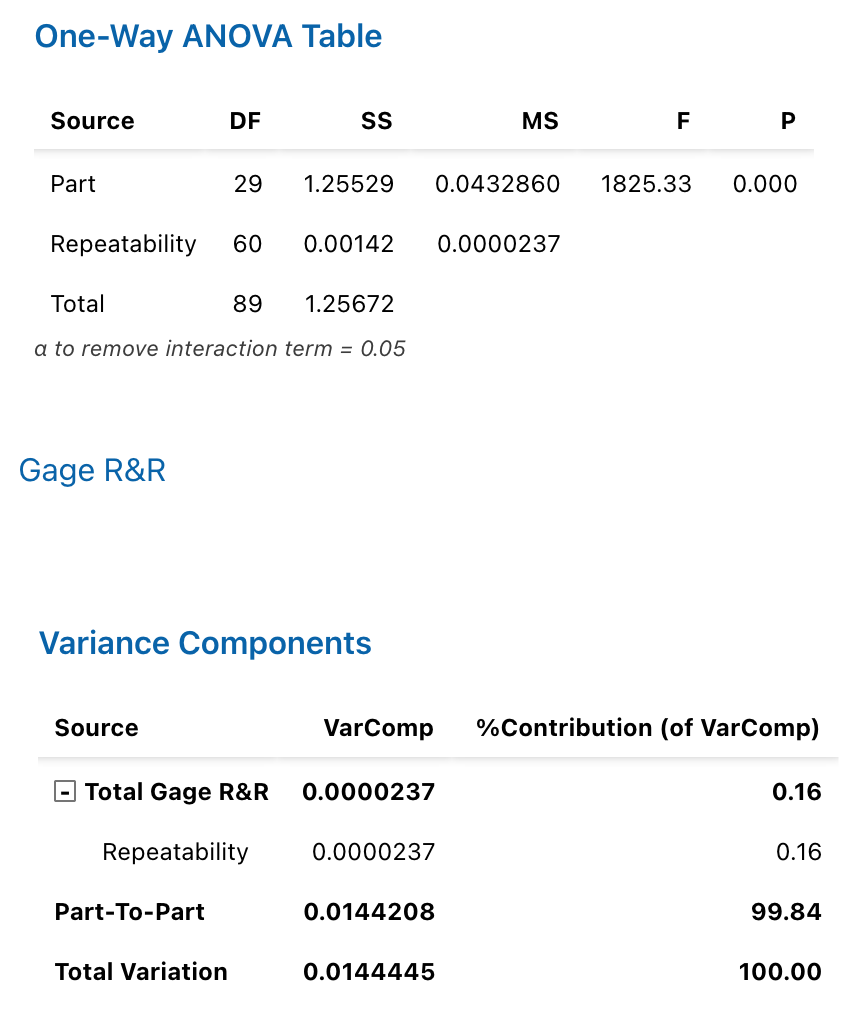

## Total Variation 0.014444470 100.000000010.2.5 Minitab

Figure 10.7: Minitab Output for Type 3 Gauge r&R Analysis (Part 1)

Figure 10.8: Minitab Output for Type 3 Gauge r&R Analysis (Part 2)

10.2.6 R

datType3$Operator <- rep(1, nrow(dat)) # as input for ss.rr() function

ss.rr(Measurement, Part, Operator, data = datType3, print_plot = FALSE)## One-way ANOVA (single appraiser):

##

## Df Sum Sq Mean Sq F value Pr(>F)

## Part 29 1.2553 0.04329 1825 <2e-16

## Repeatability 60 0.0014 0.00002

## Total 89 1.2567

##

## Gage R&R

##

## VarComp %Contrib

## Total Gage R&R 0.000023714 0.16

## Repeatability 0.000023714 0.16

## Part-To-Part 0.014420756 99.84

## Total Variation 0.014444470 100.00

##

## StdDev StudyVar %StudyVar

## Total Gage R&R 0.004869702 0.02921821 4.05

## Repeatability 0.004869702 0.02921821 4.05

## Part-To-Part 0.120086453 0.72051872 99.92

## Total Variation 0.120185150 0.72111090 100.00

##

## Number of Distinct Categories = 3410.2.7 Remarks

Variance components have been estimated using expected mean squares based on ANOVA in every software.

10.2.8 References

Gadim, H. G., & Doniavi, A. (2018). Improving structural properties of polymer fibers to design and construct fiber spinneret and optimize process parameters using response surface method and gage R&R. Journal of Mechanical Science and Technology, 32(3), 1135–1142. https://doi.org/10.1007/s12206-018-0216-7

Houf, R. E., & Berman, D. B. (1988). Statistical analysis of power module thermal test equipment performance. IEEE Transactions on Components, Hybrids, and Manufacturing Technology, 11(4), 516–520. https://doi.org/10.1109/33.16692